- Perforations : perforations can be made either between two labels on the backing paper in order to make it easier to separate them, or on the label itself in order to enable the label to be folded thus converting it into a non-adhesive ticket.

- Pre-cut : pre-cuts on the front can be made. Thus a label is composed of several parts.

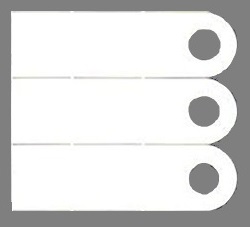

- Dot : a hole can be made in the label in order to hang it. That hole can either be simply made on the front, or on both the front and the back. The latter case requires a special tool to remove the dot.

- Notch : with an adhesive-free material (e.g. thermal paper of entry tickets), notches are cut at regular intervals on the side of the band in order to allow the label detection during printing.

- Backslit : the backslit is a cut on the label backing paper. This technique is notably used with continuous rolls in order to make it easier to remove the label from the backing paper. It also allows to maintain the backing paper on a label portion in order to lately be able to use the label.

- Special shapes : cutting tools can be made with different shapes and cutting heights.

- Tailored conditioning : on different cores diametres (25, 45, or 76mm) in rolls.